How AI & RPA Relates to Supply Chain?

Table of Contents

It is not surprising that a recent study found that AI coupled with Intelligent Automation has prompted in a 43% time savings for processes such as credit, collections, and billing. These are enormous gains for any business, but would be especially beneficial to firms wanting to successfully manage their complicated supply chains. The adoption of RPA in the supply chain has been sluggish, but given the benefits, firms are now resorting to automation to expedite product flow and gain a competitive advantage with customers.

Talk to Our Automation Expert!

+91 855-975-9735

Want to experience Intelligent Automation in Action or Need help Building the Right Automation Plan?

But how precisely may this new-age technology affect change in the way supply chains have traditionally operated? What are the fundamental changes that businesses must make before they can fully use AI along with RPA in the supply chain?

Navigating the Benefits of RPA in Supply Chain Management

Robotic Process Automation (RPA) offers a wealth of advantages for enterprises looking to optimize their supply chain operations. For those organizations that have embraced this transformative technology, the benefits are clear and substantial.

Boosts Productivity Across the Board

RPA automates repetitive, rules-based tasks throughout the supply chain, freeing up employees to focus on higher-value work. This drives significant productivity gains across every department.

Reduces Costs and Generates Savings

By eliminating manual efforts, RPA implementation leads to measurable cost reductions. Organizations can achieve substantial savings that fall straight to the bottom line.

Improves Customer and User Experience

With RPA handling routine processes more efficiently, supply chain partners and end customers enjoy enhanced responsiveness, accuracy, and overall satisfaction.

Achieves Flexibility and Scalability

RPA's software-based automation can be easily scaled up or down to adapt to changing business demands. This agility is crucial in today's volatile supply chain environment.

Array of Supply Chain Challenges Resolved by Automation

Enterprises have invested heavily in supply chain infrastructure, but complete automation and data integration remain elusive challenges.

RPA automates manual tasks to drive supply chain optimization. It enhances performance visibility through real-time KPI tracking. RPA also integrates disparate systems, reducing delays and errors. By automating and connecting supply chain operations, RPA enables more responsive, data-driven decision making.

Some of the top challenges that the supply chain process faces today include:

- Identifying supply chain enhancements to prioritize

- Identifying performance metrics that are lagging.

- Managing complex relationships with customers, transportation providers, and industrial facilities.

Supply Chain Automations Digitally Transforming Your Business and Unlocks Value

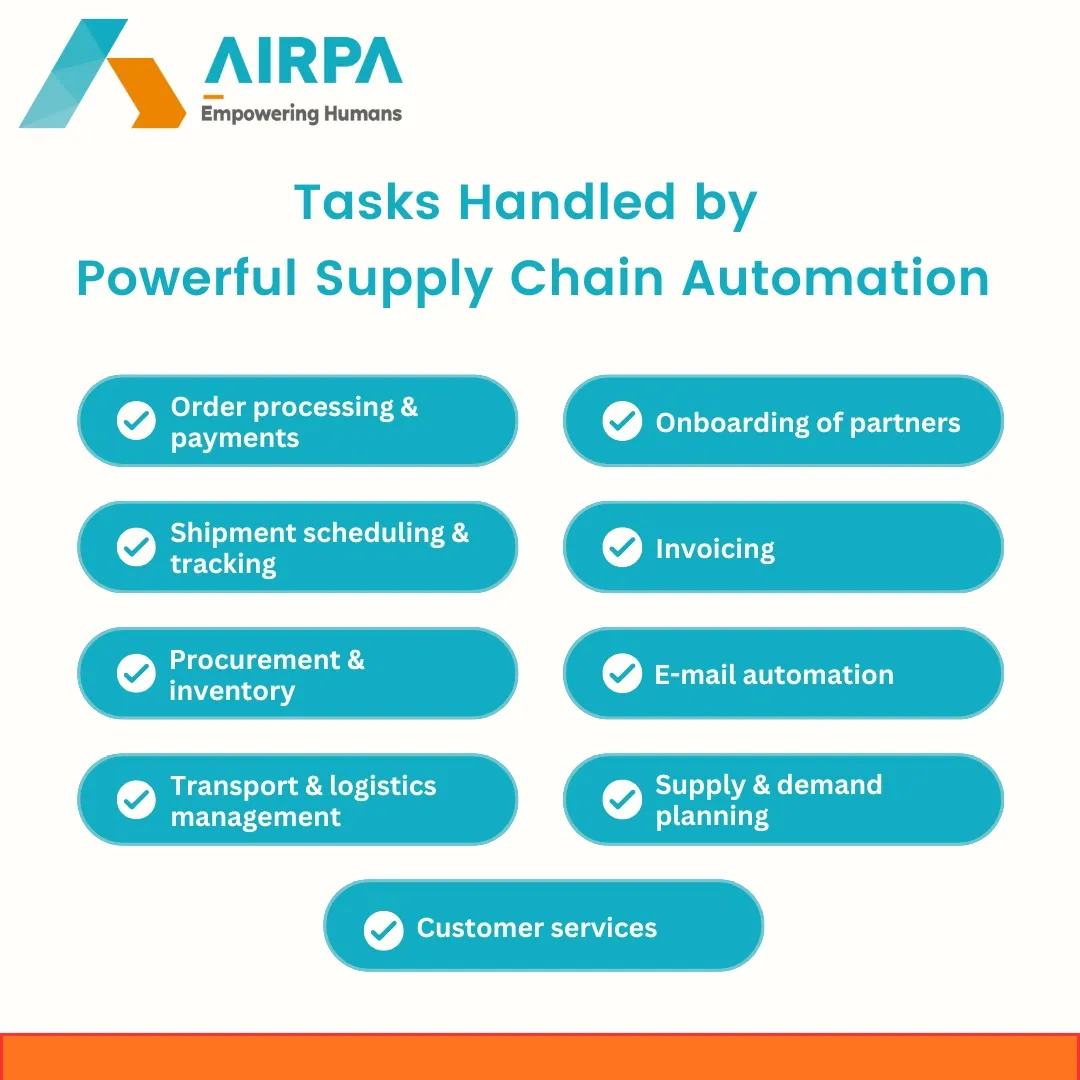

At the higher level, intelligent automation in Supply Chain can be used to predict outcomes and support complex decision making, thereby, helping employees with more than just robotic tasks.

And much more.

Know the Implementation Steps of AI & RPA in Supply Chain Management

When implementing RPA applications in supply chain management, there are a few steps you have to follow

Defining the scope of Robotic Process Automation and its objectives

Robotic Process Automation (RPA) is a transformative technology that automates repetitive, rules-based tasks across an organization's supply chain. By defining clear objectives and the scope of RPA deployment, enterprises can unlock a range of benefits, from boosting productivity and reducing costs to improving customer experience and enhancing operational flexibility. Whether automating inventory management, order processing, or other critical supply chain functions, AI & RPA empowers businesses to achieve their short-term and long-term goals through increased efficiency, speed, and data-driven decision making.

Choosing the supply chain processes to automate

Leveraging Robotic Process Automation (RPA) in the supply chain requires careful consideration. Not every process is equally suitable for automation. The goal should be finding the right balance between the costs and benefits.

A good point to start is automating inventory management. This provides clear visibility into stock levels and automates replenishment.

Next, focus on streamlining order fulfillment. RPA can ensure orders are processed and delivered accurately and on time.

Transportation management is another prime area for RPA. It allows tracking shipments and optimizing delivery routes.

By selectively automating these key supply chain functions, companies can boost productivity, responsiveness, and cost savings.

Pick the best RPA solution for your requirements

When selecting an RPA solution for your supply chain, it's crucial to thoroughly evaluate the options to find the best fit for your specific needs. Look for platforms that offer full scalability, seamless integration capabilities, robust security features, and compliance mechanisms. Above all, the starting point should be clearly defining your goals and objectives, so you can confidently invest in an RPA solution that aligns with your organizational priorities and delivers maximum value throughout your supply chain operations.

Defining the processes for managing changes

Implementing Robotic Process Automation (RPA) in supply chain management is an ongoing process with evolving challenges. The key to success lies in effectively managing the changes that arise over time. This requires diligently documenting changes and their drivers, rapidly responding to new developments, communicating transparently with stakeholders, and maintaining a laser focus on the desired outcomes. By following these essential steps, the project team can navigate the complexities of change, make informed decisions, and continuously improve the quality of services and products across the supply chain.

Establish an excellence center within your company

Establishing an RPA Center of Excellence is the crucial final step in optimizing supply chain automation. This collaborative hub should foster innovation, deliver deep expertise, think strategically about the future, and position the organization for long-term success. By creating a supportive environment that helps team members continuously improve their RPA-driven workflows, the Center of Excellence becomes an invaluable reference point and standard-bearer, guiding the organization towards greater efficiency, responsiveness, and competitive advantage across the supply chain.

Key Takeaways

RPA is an excellent supply chain management tool that allows businesses to scale quickly. It handles the majority of back-end operations and improves delivery efficiency and speed, freeing up team members' time to focus on providing superior customer care.

Are you preferring to work with a team that understands the importance of aligning business objectives with technical solutions? AIRPA offers exceptional end-to-end partnership, encompassing every stage from concept creation to delivery and long-term maintenance.

Popular Tags:

Related Articles

How Automation and AI are Reshaping the Fintech Landscape

Is AI the driving force behind fintech's rapid evolution?